Nano emulsification is revolutionizing the way we understand absorption in various industries, from pharmaceuticals to food supplements. This cutting-edge process involves breaking down substances into incredibly small particles, enhancing their bioavailability and overall effectiveness. In this comprehensive exploration, we delve into the nano emulsification process, its benefits, and the specialized equipment driving this technological leap.

Understanding Nano Emulsification

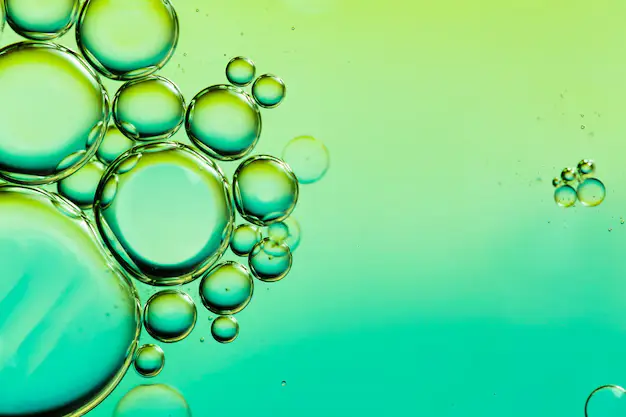

Nano emulsification refers to the process of creating nanoscale droplets of one liquid within another immiscible liquid. In simpler terms, it breaks down substances into tiny particles, typically ranging from 20 to 1000 nanometers in size. This reduction in particle size significantly increases their surface area, leading to improved solubility and absorption rates.

The Nano Emulsification Process

The process begins with the selection of suitable emulsifiers and oils, crucial for stabilizing the nano droplets. Emulsifiers like lecithin or specialized surfactants play a pivotal role in maintaining the stability of these small particles in the liquid matrix. High-pressure homogenizers or ultrasonic processors are then employed to create intense shear forces, breaking down the larger particles into nano-sized droplets.

Nano Emulsification Benefits

Enhanced Bioavailability: By reducing particle size, nano emulsification improves the absorption of substances in the body. This is particularly advantageous in pharmaceuticals, where enhanced bioavailability can lead to lower dosages and reduced side effects.

Improved Stability: Nano emulsions are often more stable than traditional emulsions, thanks to the smaller droplet size and the use of effective emulsifiers. This stability ensures longer shelf life and consistent product quality.

Versatile Applications: The technology finds applications across diverse industries, including pharmaceuticals, nutraceuticals, cosmetics, and food. It allows for the delivery of active ingredients in a more effective and controlled manner.

Nano Emulsification Equipment

Specialized equipment is crucial in achieving precise nano emulsification:

High-Pressure Homogenizers: These machines apply intense pressure to force liquids through a narrow valve, effectively breaking down particles into nano-sized droplets. They are commonly used in pharmaceutical and biotechnology industries.

Ultrasonic Processors: Utilizing high-frequency sound waves, ultrasonic processors create cavitation effects that disrupt larger particles into nano-sized ones. This equipment is preferred for its ability to operate at lower temperatures, preserving heat-sensitive substances.

Microfluidizers: These devices use microchannels to apply shear forces, resulting in uniform nano emulsions. They are prized for their scalability and efficiency in industrial settings.

Applications Across Industries

Nano emulsification has transformative implications across various sectors:

Pharmaceuticals: Enhancing drug delivery systems, improving solubility of poorly water-soluble drugs, and optimizing therapeutic outcomes.

Nutraceuticals: Increasing bioavailability of vitamins, antioxidants, and other health supplements, promoting better absorption and efficacy.

Cosmetics: Formulating skincare products with enhanced penetration and stability, delivering active ingredients deeper into the skin. Food and Beverage: Improving the sensory experience and nutritional delivery in products like beverages, sauces, and dressings.

Future Perspectives

As technology advances, so does the potential of nano emulsification. Researchers continue to explore novel emulsifiers and processing techniques to further enhance particle stability and functionality. The ongoing research aims to unlock new applications in personalized medicine, sustainable agriculture, and functional foods.

Final Thoughts

Nano emulsification stands at the forefront of innovation in absorption science, offering unparalleled benefits across industries. By harnessing the power of small particles and advanced equipment, this technology not only enhances bioavailability but also opens new avenues for product development and improved consumer experiences. As research and development progress, nano emulsification is poised to redefine standards in efficiency, efficacy, and sustainability, shaping the future of global industries.

Discover the future of absorption with NanoHempTechLabs, pioneering nano emulsification solutions that elevate your products’ bioavailability and stability. Our advanced equipment and expert formulation ensure top-tier quality across pharmaceuticals, nutraceuticals, cosmetics, and more. Maximize product efficacy and customer satisfaction with our cutting-edge technology. Schedule a call today to explore how NanoHempTechLabs can empower your wholesale business with innovative nano emulsification solutions. Join us in revolutionizing absorption and setting new industry standards.

Reference:

- Hauthal, H. (2013). Liquid foams, new approaches in raw materials, sustainability and product safety, forum for innovations. Tenside Surfactants Detergents, 50(1), 52-63. https://doi.org/10.3139/113.110234