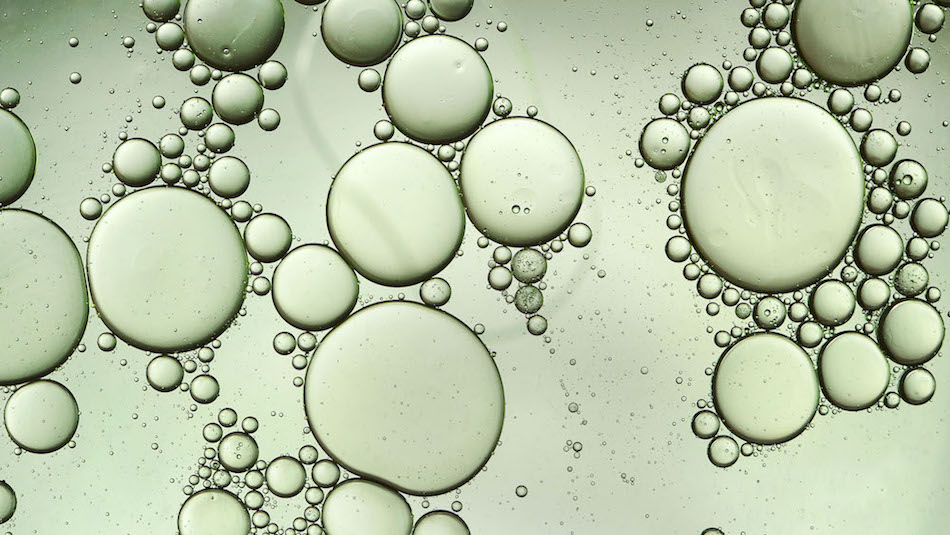

In a world grappling with escalating environmental crises, innovative technologies are stepping up as unsung heroes. Among them, Nano Emulsion Techniques stand out as revolutionary tools for tackling oil spills and purifying contaminated water. These techniques harness the power of nanoscale particles to create stable mixtures of oil and water, transforming how we address pollution. Imagine droplets so small—often measuring between 20 and 200 nanometers—that they can infiltrate and neutralize pollutants with unprecedented efficiency. Rooted in colloid science, nano emulsions are kinetically stable systems where one liquid is dispersed in another, stabilized by surfactants or nanoparticles. This stability prevents phase separation, making them ideal for environmental applications. According to research, nano emulsions enhance bioremediation by increasing the surface area available for microbial degradation, potentially accelerating cleanup processes by up to five times in some cases. With global oil spills releasing over 1.3 million tons of petroleum annually, as reported by the International Tanker Owners Pollution Federation, the urgency for such heroes is clear. These tiny titans not only disperse oil but also facilitate its breakdown, offering a sustainable path forward in our fight against ecological disasters.

The Magic Behind the Mix: Decoding Nano Emulsion Techniques

At the heart of Nano Emulsion Techniques lies the art of miniaturization. High-energy methods like ultrasonication and high-pressure homogenization shear liquids into nano-sized droplets, while low-energy approaches, such as phase inversion temperature, rely on spontaneous formation for energy efficiency. A key player is the Pickering emulsion, where solid nanoparticles, like silica or clay, adsorb at the oil-water interface, providing superior stability compared to traditional surfactants. Facts show that these emulsions can reduce interfacial tension from 44.5 mN/m to as low as 14 mN/m, enabling better dispersion. In environmental contexts, nanoparticles such as magnetite or halloysite nanotubes act as emulsifiers, costing around $600 per ton for halloysite, making them economically viable. Figures from studies indicate that nano emulsions can achieve droplet sizes under 100 nm, boosting bioavailability for microbes. For instance, graphene oxide quantum dots in nano emulsions have degraded 53% of polycyclic aromatic hydrocarbons (PAHs) in just 3.5 days, versus a mere 1.7% in controls. This technique minimizes environmental impact by using biodegradable stabilizers, aligning with sustainable practices. As nanotechnology advances, these methods are becoming more accessible, with production scales reaching industrial levels for real-world deployment.

Conquering Oily Catastrophes: Nano Emulsion for Oil Spill Cleanup

When oil slicks blanket oceans, Nano Emulsion for Oil Spill Cleanup emerges as a frontline defender. By breaking crude oil into nano-sized droplets, these emulsions increase the oil’s surface area, making it easier for oil-eating bacteria to feast. In the aftermath of the Deepwater Horizon spill, which dumped 184 million gallons into the Gulf of Mexico, nano-enhanced approaches could have expedited recovery. Research highlights Oil Spill Cleanup Nano Emulsion using polyvinylpyrrolidone-coated magnetite nanoparticles, achieving 100% crude oil removal in 48 hours when combined with bacteria—surpassing 65% by nanoparticles alone and 90% by microbes solo. Clay-based nanomaterials, like nontronite, amplify bacterial growth fivefold, degrading 58% of alkanes in 37 days compared to 45% without aid. Mechanisms involve nanoparticles stabilizing Pickering emulsions, preventing coalescence and enhancing dispersion even in turbulent seas. Facts reveal that such techniques are minimally weather-dependent, unlike booms or skimmers, and can handle diverse oil compositions from light crude to heavy tars. With annual global spills affecting 35 billion gallons of transported oil, these methods reduce long-term ecosystem damage, preserving marine life and coastlines. Innovations like magneto-responsive bacteria, coated with 70-100 nm thick nanoparticle shells, allow magnetic collection post-cleanup, adding a layer of control.

Purifying Polluted Flows: Nano Emulsions Revolutionizing Water Treatment

Beyond spills, Nano Emulsion Techniques shine in water purification, addressing oily wastewater from industries and spills. Nanofiltration membranes embedded with nanocomposites separate emulsions with over 99% efficiency, filtering droplets as small as 5 nm. In coastal regions, where oily pollution threatens drinking sources, these techniques remove dispersed oil and soluble contaminants. For example, polyethersulfone membranes with embedded nanoparticles enhance flux rates up to 38,000 L/m²/h while maintaining 99.97% separation for chloroform-water mixtures. Cellulose nanocrystals in nano emulsions adsorb contaminants via their rod-like structure, selectively purifying streams. Figures show that nanoemulsions can soften water and eliminate biological impurities, with water-in-oil or oil-in-water types dispersing pollutants for easy removal. A 2020 review notes that sustainable nanotechnology has cut purification costs by improving membrane longevity and reducing fouling. With 2.2 billion people lacking safe water access, as per UNESCO, these heroes are vital. Bio-based nano emulsions, using xanthan gum and silica, offer eco-friendly dispersion, degrading organics catalytically. Efficiency data indicates up to 99.98% removal in pH-varying environments, making them adaptable for global use.

Triumphs from the Trenches: Real-World Applications and Impacts

Real-world deployments underscore the heroism of Oil Spill Cleanup Nano Emulsion. In lab simulations mimicking the Gulf War spill of 38 million gallons, nano-enhanced bioremediation degraded hydrocarbons 50% faster. Case studies with halloysite nanotubes functionalized for hydrophobicity stabilized emulsions, recovering 90% of hexadecane in six days. In water purification, projects using CNC nanofiber membranes treated industrial effluents, achieving 99.1% efficiency across 10 cycles. Facts from Concordia University research show clay nanomaterials creating larger bacterial habitats in emulsions, accelerating degradation. Multi-shell nano-carbo scavengers, bio-compatible solids, have remediated petroleum spills with capillary forces drawing oil into pores. Figures reveal absorption capacities up to 415 cm³/g for modified aerogels, with densities as low as 0.1 mg/cm³ ensuring buoyancy. These applications have mitigated pollution in coastal zones, where nanomaterials outperform traditional dispersants by being less toxic. Success in separating nanoemulsions from wastewater highlights their versatility, with fluxes of 22,200 L/m²/h in cotton-based systems. Such triumphs not only clean but also restore ecosystems, proving nano emulsions as reliable environmental guardians.

Envisioning a Greener Tomorrow: Innovations on the Horizon

Looking ahead, Nano Emulsion for Oil Spill Cleanup and purification promises even greater feats. Emerging multi-functional nanoparticles could integrate sensing for real-time monitoring, with AI optimizing emulsion formulations. Research aims at scaling low-energy methods to cut production energy by 90%, making them feasible for remote spills. Figures project a nanotechnology market for environmental remediation reaching $100 billion by 2030, driven by these techniques. Innovations like self-propelled nanomotors, coated hydrophobically, navigate spills autonomously, collecting oil droplets efficiently. For water, advanced nanoemulsions might encapsulate heavy metals alongside oils, expanding purification scope. Challenges like nanoparticle toxicity are being addressed through green synthesis, ensuring biocompatibility. With climate change intensifying spills—evidenced by rising incidents— these advancements offer hope. Collaborative efforts, like those post-Deepwater Horizon, accelerate adoption, potentially halving cleanup times globally.

Embracing the Nano Revolution: A Call to Action

In conclusion, Nano Emulsion Techniques are true environmental heroes, combating oil spills and purifying water with ingenuity and precision. From stabilizing Pickering emulsions to achieving near-perfect separations, they embody sustainable innovation. As we face mounting pollution, embracing these tiny titans could safeguard our planet for generations.

Discover the power of NanoHempTechLabs‘ innovative wholesale products harnessing Nano Emulsion Techniques for superior environmental solutions. Our cutting-edge Nano Emulsion for Oil Spill Cleanup breaks down pollutants into nano-sized droplets, accelerating bioremediation by up to five times, as seen in real-world triumphs like Gulf spill simulations. Ideal for water purification, our Oil Spill Cleanup Nano Emulsion achieves 99% efficiency in removing contaminants, safeguarding ecosystems and coastlines. Eco-friendly, scalable, and backed by facts—join the nano revolution today! Schedule a call with our experts to explore wholesale opportunities and customize your order for a greener future. Let’s clean up together!

Reference:

- Ghasemi, P. (2018). Development of raw and treated flax straw for oil spill cleanup.. https://doi.org/10.25071/10315/35415

- Gohlke, J., Doke, D., Tipre, M., Leader, M., & Fitzgerald, T. (2011). A review of seafood safety after the deepwater horizon blowout. Environmental Health Perspectives, 119(8), 1062-1069. https://doi.org/10.1289/ehp.1103507

- Li, D., Zhu, F., Li, J., Na, P., & Wang, N. (2013). Preparation and characterization of cellulose fibers from corn straw as natural oil sorbents. Industrial & Engineering Chemistry Research, 52(1), 516-524. https://doi.org/10.1021/ie302288k